What Are The Precautions During The Production Process Of Vacuum-brazed Core Drill Bits?

In the production process of vacuum-brazed core drill bits, we need to ensure that every step meets the production requirements and ultimately provides customers with high-quality products.

Detailed Analysis Of Project Implementation

1. Consider the customer's requirements, including drawings, materials, prices, packaging, cutter heads, colors, logos, samples, mass production quantities, reports, etc., and communicate their delivery time, transportation method, contract, final payment, etc.

2. Consistency in supplier assessment, evaluation, and information transmission and communication.

3. Communicate with the project team about the product implementation, including technical and detailed assessments. Only after all three parties can accept it can the prototype be implemented.

4. If the printing results are evaluated by the three parties and meet the requirements, mass production can begin.

Production Links That Need To Be Considered For Product Launch

1. Material consistency of incoming materials, including material acceptance report.

2. Turning processing needs to be more precise.

3. Clean the base body with a metal cleaning agent to remove rust stains and oil stains. It needs to be dried to avoid rust again.

4. Perform sandblasting to remove rust stains on the surface again and turn it into a frosted surface, which makes it easier to paint.

5. The glue should be applied evenly and the glue formula should be stable.

6. The sand should be applied evenly and the diamond particle size should be accurate.

7. Bake in the brazing furnace, and pay attention to the control of time and temperature. After brazing, check again whether the diamond particles are enough, and if there are not enough, you need to make up.

8. Inspect the threads to see if they are accurate and usable.

9. When spraying paint, pay attention to the accuracy of the color and location, and make sure it is dry enough to prevent scratches.

10. Check the dimensions of the threads and product again, and re-make the threads with problems.

11. Pay attention to position, clarity, and accuracy when laser marking.

12. After marking, apply anti-rust oil to avoid rust at the marked location.

13. Packaging: Accuracy inspection and quality inspection of packaging materials according to customer requirements.

(The placement requirements, bumps, and turnover of all production links should consider the qualification of the product)

Things To Consider About Products

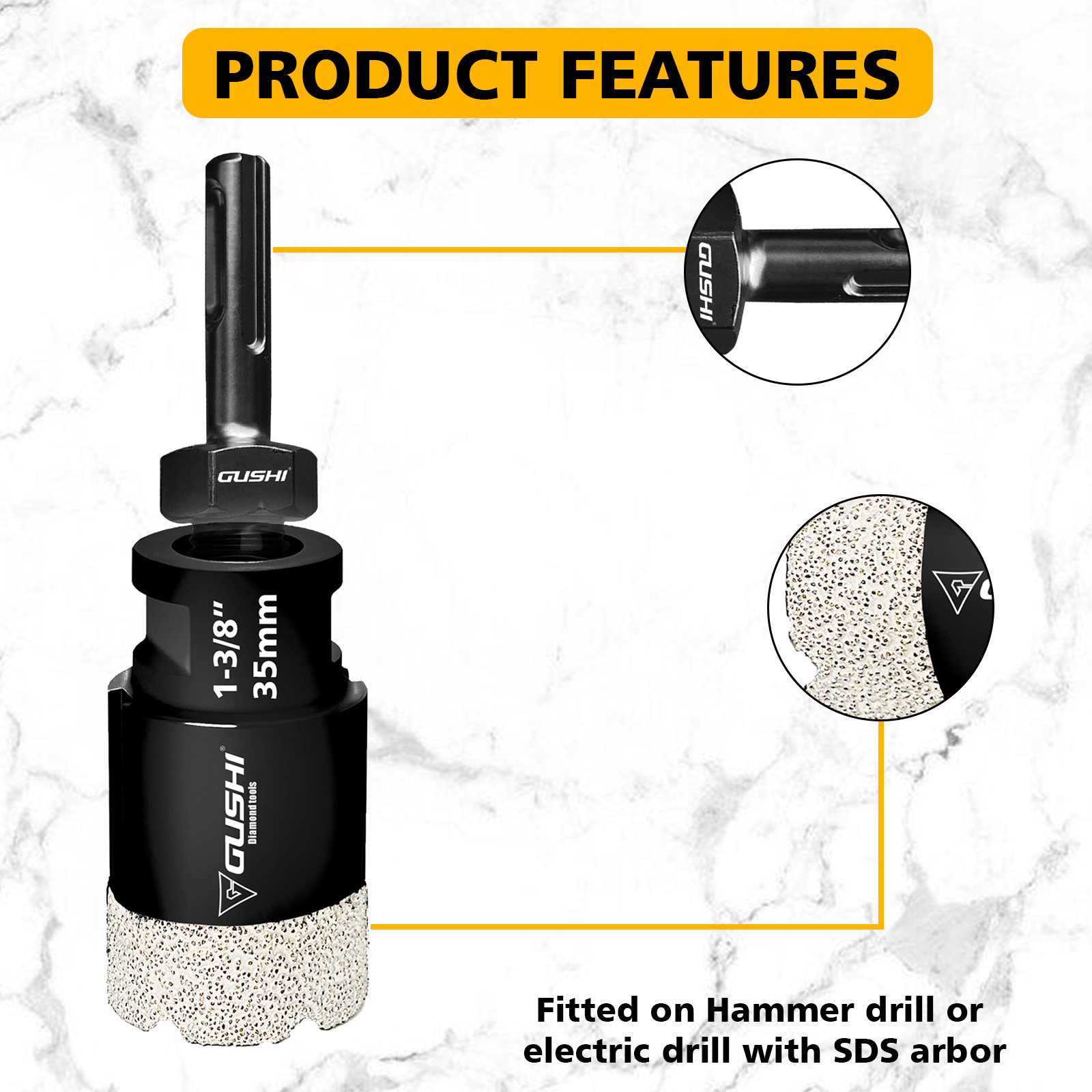

Product material, size, angle, length, width, height, thickness, flatness, diamond particle size and thickness of the cutter head, cutter head size, color, logo color, packaging, boxing, logo, mark, etc.

The above are the details and requirements we pay attention to when producing vacuum-brazed core drill bits. If you have other curious things, you can ask me anytime!